What Are The Advancements In Electrical Engineering For Efficient Power Transmission?

engineeringlearn.com - engineeringlearn

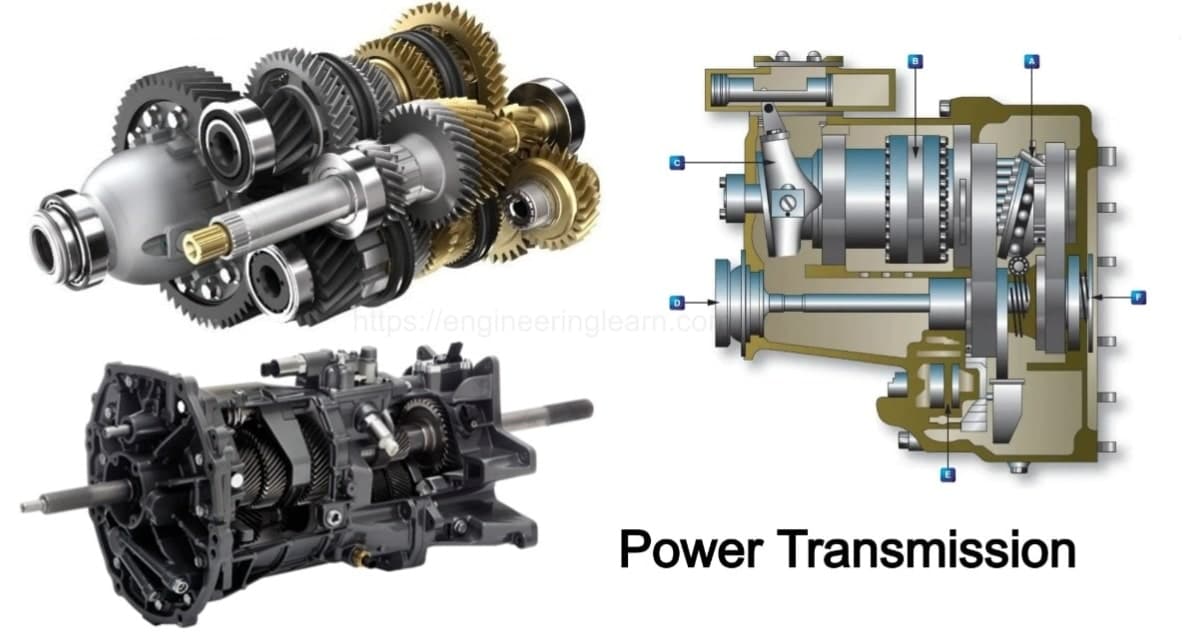

Power transmission is a crucial aspect of mechanical engineering as it helps in transferring power from one location to another without any loss. The process of power transmission involves the transfer of energy from the source to the end-use equipment for performing various operations. The power generated by the source is transmitted via a driving element to the driven element to perform work. This article will delve into the various types of power transmission systems used in mechanical engineering. The first type of power transmission system is the belt and pulley system, which is the most common method used in mechanical engineering. In this system, a belt connects the driving pulley to the driven pulley and transfers power from one pulley to the other. The belt can be made of different materials, including leather, rubber, or synthetic materials, based on the application requirements. This system is useful in situations where there is a need for speed reduction or speed increase. Another common power transmission system used in mechanical engineering is the chain drive. The chain drive uses a chain to transfer power from the source to the end-use equipment. It is used in situations where a large amount of torque is required or where the distance between the source and the end-use equipment is significant. It is commonly used in industrial applications such as in conveyors, elevators, and agricultural machinery. Gears are also used as power transmission systems in mechanical engineering. Gears are usually in the form of toothed wheels that mesh with one another to transfer power from the source to the end equipment. The gear system is widely used in situations where there is a need for power transmission at high speeds and where various speed ratios are required. Gears can be made of different materials, including steel, plastic, or brass, and can be designed for a wide range of applications. The fourth type of power transmission system in mechanical engineering is the coupling system, which is used to transmit power through a direct connection between the driving and driven equipment. There are different types of couplings available, including the rigid coupling, flexible coupling, and fluid coupling, each with its advantages and disadvantages. Couplings are commonly used in situations where there is a need for a direct and uninterrupted power transmission. Hydraulic systems are also used as power transmission systems in mechanical engineering. In a hydraulic system, a fluid such as oil is used to transfer power from the source to the end-use equipment. A hydraulic pump is used to pump the fluid from the source to the equipment, and a hydraulic cylinder is used to convert the fluid's pressure into mechanical work. Hydraulic systems are commonly used in industrial and mobile applications such as in construction equipment, aircraft, and automobiles. Similarly, pneumatic systems are used as power transmission systems in mechanical engineering. In a pneumatic system, compressed air is used to transfer power from the source to the end-use equipment. A pneumatic pump is used to pump the compressed air from the source to the equipment, and a pneumatic cylinder is used to convert the pressurized air into mechanical work. Pneumatic systems are commonly used in applications such as in brakes, clutches, and lifting equipment. Finally, electrical systems are also used as power transmission systems in mechanical engineering. In electrical systems, electric power is used to transfer power from the source to the end-use equipment. Electrical power is generated by a power source such as a generator or battery and is transmitted through wires or cables to the end-use equipment. Electrical systems are widely used in various applications such as in electric motors, lamps, and electronics. In conclusion, power transmission is an essential aspect of mechanical engineering that involves the transfer of energy from one location to another without any loss. The different types of power transmission systems used in mechanical engineering include belt and pulley systems, chain drives, gears, coupling systems, hydraulic systems, pneumatic systems, and electrical systems. The selection of the power transmission system depends on the specific application requirements such as the amount of torque required, speed, and distance between the source and the end-use equipment. These systems have different advantages and disadvantages, and the selection of the appropriate system should be based on the specific application requirements.

Post a Comment for "What Are The Advancements In Electrical Engineering For Efficient Power Transmission?"